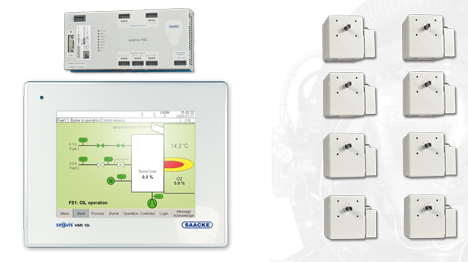

se@vis pro

The main points

- Suitable for all SAACKE burners

- Automatic firing sequence controller for 3 fuels

- Allows simultaneous firing of alternative fuels (e.g., biogas, by-products or dust)

- Electronic compound regulation with 8 channels in 8 operating modes

- 10” touch screen for simple, intuitive operation

- 10 integrated controllers

- Certified safety with SIL 3 according to IEC 61508

- Certified by LR, GL, DNV, RINA, ABS, PRS, AGA

Outstanding performance for complex plants

When it comes to controlling burners and system peripherals comprehensively and conveniently, seavis pro has worldwide no rival. This controller offers extensive interfaces and visualizes all the processes relevant to the combustion system. Even the basic version controls 8 channels, features 10 integrated controllers and is outstanding for complex applications, such as the combustion of dusts or mixed simultaneous firing with alternative fuels.

Despite the diversity, however, the system remains astonishingly simple. Its basic components are the fail-safe FSC basic unit, the large HMI touch screen, and up to 12 fail-safe servomotors. The fail-safe components are connected via Safe Ethernet, making seavis pro safe, uncomplicated, and universally expandable. The core modules are stored on a compact mounting plate and, as such, enable particularly rapid commissioning.

In operation, seavis pro displays the signals from all the connected components on its large touch screen and controls the actuators extremely precisely with a resolution of 2000 steps. The simple parametrization allows for problem-free use of 3 fuels. Or simultaneous firing of two fuels. Or fuel change without load dropping, water injection in heavy oil firing operation mode, and an intelligent warming up program for all heat generators.

The data compiled during operation can be viewed conveniently on the display and analyzed using trend indicators. Comprehensive display of the initial value fault messages means troubleshooting in the system is also quick and easy. In addition, the basic version can already be integrated into the process control and communication system via bus coupling with remote control.

Possible applications for seavis pro are hardly limited to highly complex requirements: This control system is also excellent for firing with gases or liquids that have low heat values, for wood or carbon dust or for switching between different fuels without having to switch off the combustion system to do so.

This combination of versatility, reliability, and ease of use makes seavis pro totally unrivalled – and very reassuring: After all, the entire system is certified with SIL 3 in accordance with IEC 61508 and, in addition to the certificates from numerous maritime classification societies, it has also been awarded the approval of the Australian Gas Association.