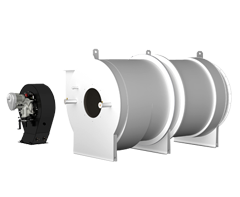

Combustion chambers for high-temperature applications

CCS-HT

Capacity

1 – 56 MW

Fuels

Suitable for all standard fuels, low calorific liquids and gases as well as numerous of dusty fuels

Applications

For drying, calcination as well as heating and recovery of process gases

The main points

- Outlet temperatures from 600 - 1200°C

- Can be operated with any burner type

- Suitable for all standard fuels, low-calorific liquids and gases as well as numerous pulverized fuels

- Large control range with very low emission values

- Short startup times and precise control

- Long maintenance intervals and service life

Hot gases for high temperatures

Hot gas generators are used if hot gases are needed for direct drying or for other processes. Additional processes can also take place in the gas flow. For example flue gas, exhaust air or exhaust vapors (called mixed gas below) can be disposed of thermally.

With the CCS-HT combustion chamber series, SAACKE offers standardized hot gas generators in a wide load range: Proven thousands of times in real applications, they are suitable for all standard fuels as well as numerous special fuels and can be used to operate any SAACKE burner in almost any installation position.

Regardless of the size, all CCS-HT combustion chambers consist of a stable double shell with fireproof refractory brickwork. The small sizes are bricklined ex works and delivered ready for mounting, while the larger combustion chambers are bricklined at the installation side due to the great weight involved. The mixed gas enters the double shell tangentially, flows between the inner and outer shell and is mixed together with the hot gas at the end of the combustion chamber. The gas cools down the steel shell in this manner, and also serves, by varying the quantity, as a correction mechanism to maintain a precise temperature at the output of the hot gas generator.

The temperature profile at the output of the combustion chamber is also especially homogenous due to the sophisticated design: The mixed gas is guided by free flowing for the best results, thus guaranteeing a high level of efficiency for downstream processes.

Almost any burner is available for selection. All burners are operated with a high air excess of 60-80%, providing optimum burnout with an especially wide control range. The furnace temperature of about 1400°C is possible because of the high air excess, which also reduces wear on materials, and the very low emission level. Depending on the fuel and firing capacity, the hot gas temperature ranges between 600 and 1200°C. The refractory brickwork of the CCS-HT is relatively thin compared to other designs due to the cooled double shell. This allows for fast, precise control with very short startup times.

Because of their high temperature level, the hot gases can also be used with outstanding results to produce thermal energy from other by-products and residues. Whatever the application, each plant is individually configured from standard components and tailored to the requirements of the relevant drying material or the specific process. In this manner, expert SAACKE engineering not only guarantees the highest availability and lowest emission values, but especially an outstanding service life for the combustion chamber.