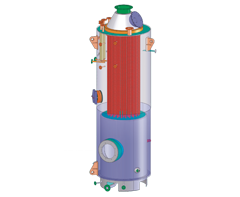

FMB-VS

Fired marine boiler

Capacity range

Up to 5 t/h

Dimensioning pressure

Up to 1.2 MPa

Design features

The FMB-VS is a vertically arranged steam boiler. Heat is transferred through a smooth flame tube and a number of corrugated flue gas tubes for flue gas return. If necessary, the convection area can also be fitted with pin tubes.

The furnace cover plate has a pronounced dome shape, which gives the FMB-VS greater stability for ship vibrations and protects that part of the boiler against overheating to some extent because residue cannot be deposited in that area as easily.

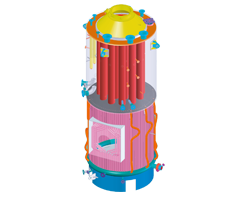

FMB-VM

Fired marine boiler

Capacity range

6 – 25 t/h

Dimensioning pressure

Up to 1.0 MPa

Design features

The FMB-VM is a steam boiler constructed according to the water-tube boiler principle for the medium load range. Radiant heat is transferred in the diaphragm wall of the cylindrically shaped combustion chamber while convection heat is transferred by special pin elements (pin tubes) or corrugated flue gas tubes. If necessary, the convection area can also be equipped with corrugated flue gas tubes up to a steam output of 16 t/h. Natural water circulation is ensured for all parts of the boiler by several downpipes leading to the outside which connect the water/steam drum with the ring-shaped collecting line on the bottom of the boiler. The furnace cover plate with a pronounced dome shape gives the FMB-VM greater stability for ship vibrations and protects that part of the boiler against overheating to some extent because residue cannot be deposited in that area as easily before it can collect on the furnace cover plate.

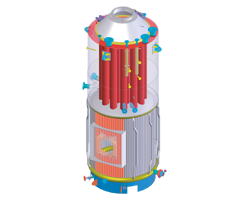

FMB-VL

Fired marine boiler

Capacity range

14 – 45 t/h

Dimensioning pressure

Up to 1.8 MPa

Design features

The FMB-VL is a steam boiler constructed according to the water-tube boiler principle for the medium to high load range. Radiant heat is transferred in the diaphragm wall of the cylindrically shaped combustion chamber while convection heat is transferred by special pin elements (pin tubes). Natural water circulation is ensured for all parts of the boiler by several downpipes leading to the outside which connect the water/steam drum with the ring-shaped collecting line on the bottom of the boiler. The furnace cover plate with a pronounced dome shape gives the FMB-VL greater stability for ship vibrations and protects that part of the boiler against overheating in some cases because residue cannot be deposited in that area as easily before it can collect on the furnace cover plate.

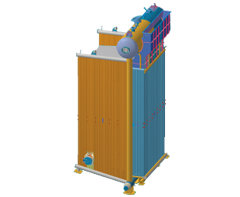

FMB-VD

Fired marine boiler

Capacity range

30 – 110 t/h

Dimensioning pressure

Up to 2.5 MPa*

*Can be adapted if requested by the customer

Design features

The FMB-VD is a type D boiler. It is fired from above and has a design reminiscent of a traditional diaphragm-wall boiler, which has proven most reliable on ships. Radiant heat is transferred in the furnace. The convection area consists of special pin tubes, each one of which has high heat transfer capacity. Significantly greater efficiency is achieved in partial load operation due to the enlarged heating surface. The convection area can be cleaned using steam-operated soot blowers. Externally located downpipes ensure natural water circulation in all areas of this water-tube boiler.

The FMB-VD is designed in principle for producing saturated steam, but it can also be equipped with superheater elements. Pressure stages and steam temperatures are available if needed.

FMB-HF

Fired marine boiler

Capacity range

Up to 10 t/h

Dimensioning pressure

Up to 1.2 MPa

Design features

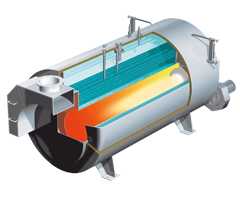

The FMB-HF is a horizontally arranged three-pass heating boiler. Based on the two passes in the convection section, the highest possible efficiency is achieved for marine boilers. Heat is transferred through smooth flame tube corrugated in parts and a number of smooth flue gas tubes. These flue gas tubes and the furnace are accessible for cleaning and maintenance through hatchways on the rear chamber wall. The flue gas area is fitted with smooth flue gas tubes.

FMB-VF-LONOX

Fired marine boiler

Capacity range

Up to 18 t/h

Dimensioning pressure

Up to 1.0 MPa

Design features

The FMB-VF-LONOX is a vertically arranged double-pass steam boiler. Heat is transferred through a partially corrugated smooth flame tube and a number of smooth flue gas tubes. The innovative design of the flame tube inlet allows for minimum refractory brickwork on the burner, which improves availability considerably.

Low NOx emission

The FMB-VF-LONOX was designed for integrating low-NOx combustion systems. Low-NOx burners achieve the lowest emission value through partially external flue gas recirculation. Together with MGO (marine gas oil) fuels, they will help to ensure that boilers can be operated in all harbors around the world in the future, since they represent the latest state of the art onshore and offshore. Burner systems that are fired with heavy oil can be equipped with water injection to lower emissions of solids.