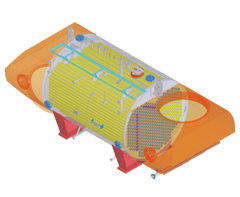

EMB / EME-HST

Ship flue gas boiler

Capacity range

On request

Dimensioning pressure

Up to 2.2 MPa

Design features

The EMB/EME-HST is a horizontally arranged flame tube flue gas boiler or economizer which can also perform the function of a silencer in the flue gas system to some extent. Heat is transferred by smooth flue gas tubes that are easy to clean and maintain.

The EMB-HST flue gas boiler has its own steam range and works independently of other boilers in the system.

The EME-HST flue gas economizer must be connected to a fired boiler or a separate steam drum through forced circulation.

Both the EMB-HST and the EME-HST can be operated in dry running in an emergency.

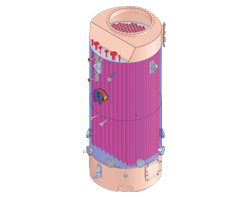

EMB / EME-VST

Ship flue gas boiler

Capacity range

On request

Dimensioning pressure

Up to 2.2 MPa

Design features

The EMB/EME-VST is a vertically arranged flame tube flue gas boiler or economizer which can also perform the function of a silencer in the flue gas system to some extent. Heat is transferred by smooth flue gas tubes that are easy to clean and maintain.

The EMB-VST flue gas boiler has its own steam range and works independently of other boilers in the system.

The EME-VST flue gas economizer must be connected to a fired boiler or a separate steam drum through forced circulation.

Both the EMB-VST and the EME-VST can be operated in dry running in an emergency.

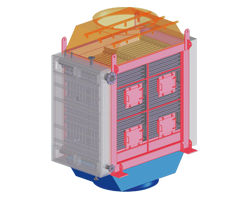

EME-VFT

Ship flue gas economizer

Capacity range

On request

Dimensioning pressure

Up to 2.2 MPa

Design features

The EMB-VFT is a conventional vertically arranged flue gas economizer with forced circulation which can also perform the function of a silencer in the flue gas system to some extent. Heat is transferred through water tubes with fins to increase the heating surface.

The water tubes are combined in removable modules. Each module can be removed independently from the casing of the EME-VFT for repair or maintenance purposes. Because the collecting lines are arranged externally, one or more modules can be isolated and shut down. The EME-VFT is easy to clean because it has connections for water nozzles and soot blowers as well as maintenance hatches.

The EME-VFT can also be operated in dry running in an emergency.