Blow-out and blowdown control

The main points

- Reduced maintenance overhead for the steam generator

- Prevents unnecessary blow-out loss

- Extended travel time and service life of the boiler

- Suitable for all boiler variants and operating modes

- Easy to retrofit

- Short amortization time

Eliminating ongoing loss and extending service life

The quality of the boiler water helps to determine the efficiency and service life of the entire boiler plant. The most important factors determining quality are the concentrations of corrosive gases and mineral components that are reduced by appropriate water treatment and handling of condensate. Losses occur due to blow-out and blowdown to a greater or lesser extent based on system characteristics and depending on the type of water treatment. These items are often ignored when considering energy, however, because the focus is not on that problem.

Nevertheless, optimized blow-out and blowdown control can not only extend the service life of the steam boiler plant, but above all can save considerable costs and lower impact on the environment.

Blow-out generally occurs continuously, whereas blowdown is periodic. Both processes are usually not sufficiently monitored, resulting in expensive loss of heat through overdosing or shortening of the service life of the plant.

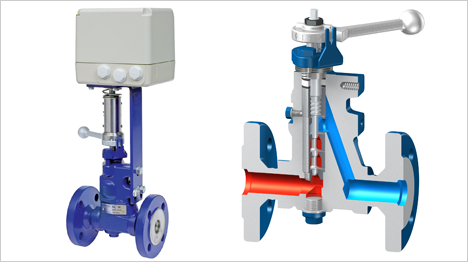

Optimized blow-out and blowdown control consists essentially of a conductivity probe, the blow-out and blowdown valves as well as automatic control of the system. The probe continuously monitors the salt content of the water. It provides exact values about the actual status of the heat carrier. The downstream control system then keeps the salt content within narrow, defined limits and controls blow-out and blowdown precisely and reliably.

Although all control systems are designed essentially the same, they are planned and fine-tuned individually. SAACKE customizes each solution to specific needs, making use of proven standard components. The size, design and operating mode of the steam generator make no difference. All control systems ensure that steam generators are always operated at exactly defined limit values. This not only extends the life of the plant, but also ensures that not a single liter of hot water is wasted unnecessarily.