Speed control

The main points

- Saves up to 80% on power consumption

- Can be easily retrofitted on existing plants

- Can be used for all types of burners and all heat generators

- Very short amortization times of < 2 years possible

- Improves control response, especially in the low load range

- Reduces mechanical load on fan and burner components

- High availability, long service life

Saving energy and improving control response

Without speed control, combustion air fans always run at full capacity, even if the burner is being operated at low load. This is not only loud, but also consumes a great deal of electrical power. When firing plants are operated at partial load or low load, speed control can use its strengths to advantage by reducing the speed of the combustion air fan when the burner does not need full air flow. This saves valuable energy that would otherwise be wasted on the air dampers.

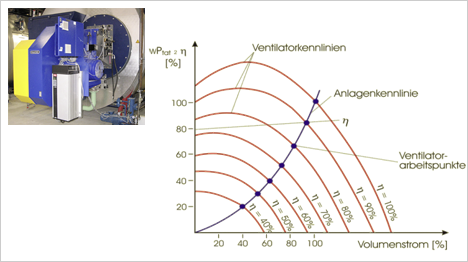

Normally fans can only work efficiently at a constant speed within a narrow operating point. Therefore they are usually designed for full load, but they work inefficiently if the full air flow is not being received. Speed control makes it possible to extend this optimum operating range considerably. The fan almost always runs efficiently, no matter how much air is currently required for combustion. Both the design of the fan and its speed also have little impact. The boiler house is also quieter: Speed control lowers the noise produced by the fan and on the throttle butterfly damper by up to 25 dB.

Speed control technology has been proven a hundred thousand times over in actual practice and is based on a simple principle: A frequency converter changes the input frequency supplied to the motor. Because the speed of the motor depends directly on the excitation frequency, the motor turns correspondingly slower or faster. To control firing plants, however, proper functioning must also be ensured by continuous speed monitoring (for example with an appropriate recorder or by monitoring the differential pressure of the combustion air).

The big advantage of modular technology is that it can be retrofitted on almost any plant, burner and fan. The change can be heard clearly the next time the plant starts and firing costs are lowered immediately.