O2/CO Control

The main points

- Minimizes O2 excess and reliably complies with CO limits

- Reduces flue gas loss

- Very short amortization times of < 2 years possible

- Can be used for all types of burners and all heat generators

- Easy to retrofit

- Fast response time of < 15s

- Long service life

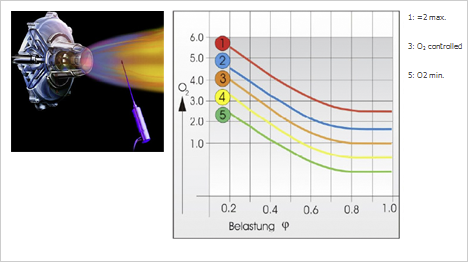

Minimum O2 excess – reduced flue gas loss

The ambient conditions of a combustion plant change from day to day and from summer to winter. The temperature of the combustion air and oil are subject to especially strong fluctuation, as are relative humidity, oil viscosity, the heat value of the fuel gas and atmospheric pressure. The flame of the burner is directly affected by these changes. It is therefore set during commissioning so that even under very unfavorable circumstances there is enough oxygen present for complete burnout. This setting is inflexible and is based on the assumption that all unfavorable circumstances coincide. In most cases, however, such a setting is excessive and the flame receives more atmospheric oxygen than necessary.

A "safety air excess" protects against impermissibly fluctuating conditions, but is very expensive: The excess air results in increased flue gas losses and also consumes unnecessary electrical energy. These losses account for 1-2% of the fuel that is used on average. They represent an additional load not only for the budget, but also for the environment.

If the combustion plant has electronic fuel-air compound control, the remedy is simple. O2 control can generally be fitted with little expense. The additional component consists essentially of a lambda probe (an oxygen sensor) together with an analyzing unit: The probe mounted in the flue gas channel continuously records the residual oxygen content in the flue gas and sends the corresponding signal to the burner control system. The control system can then respond appropriately, regulating the amount of air and limiting it to what is absolutely necessary. When used together with an additional CO probe, which has recently become available for gas combustion systems, the control response is even narrower and more precise. The burner control system is capable of keeping the air excess extremely close to the CO limit.

Each control system is individually adapted by SAACKE based on a few standard components. All solutions have been proven thousands of times over and are based on a very simple principle: The probe and analyzing unit require little time for installation and can be inserted into all commonly used burner control systems with no problems. Then the next time the plant is started, you save fuel, lower emission values and reduce the impact on the environment. Especially good news: the short amortization time is usually less than two years.