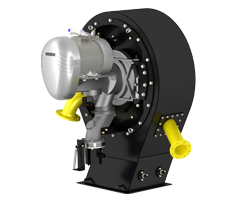

SKVG

Capacity range

1 – 55 MW

Fuels

Standard fuels and virtually all gaseous and liquid special fuels

Applications

On ships and on land, both in standard and process applications

The main points

- Burner concept with unmatched flexibility

- Produces energy reliably from even the heaviest fuels and wastes with low emissions

- Suitable for virtually all heat generators and furnace geometries

- Sturdy rotary cup atomizer design based on technology proven thousands of times over

- Simultaneous combustion of multiple gases and oils

- Very large control range for liquid and gaseous fuels

- Low fuel supply pressure and low preheating temperature requirement

- High efficiency, low maintenance costs and long service life

- In compliance with European directives and requirements of ship classification societies

Proven, flexible technology for standard and special solutions

With the SKVG rotary cup atomizer series, SAACKE offers a burner concept with performance capabilities and variability that far exceed comparable solutions of other manufacturer: This series covers the range of high load ranges, high control ranges and the heaviest fuels, which place extreme requirements on a firing plant, yet still offers high availability and safety.

The advantages of rotary cup atomizer technology are especially impressive when it comes to combustion of super-heavy oils or thermal utilization of wastes: Despite the heavy fuels, it offers maximum reliability with optimal burnout, very low emission values and an extremely long service life.

Like all SAACKE rotary cup atomizers, SKVG also offers a decisive advantage for combined firing systems with liquid and gaseous fuels: The control range is equally large for both (up to 1:8). That means no compromises need to be made.

Of course all models, including the basic model, are suitable for all standard fuels: The burner is available for use with light and heavy fuel oil and in variants for standard gases or as a combined gas and oil burner. If required, it can burn different gases and liquids simultaneously with simultaneous firing, in a wide range of combinations. The duoblock burner design with a separate fan increases firing flexibility considerably and allows for applications with air preheating or the use of unusually high furnace pressures.

Individually planned firing plants on land or at sea are the great strength of SKVG. There are just a few limits to the variability of this series – it can be adapted to almost any heat generator and forms the core of process firing systems that fulfill challenging requirements.

The high energy efficiency and low maintenance cost represent the results of decades of continuous development work.

With all its flexibility, the SKVG is uncompromising in just two attributes: high quality and extremely long service life.