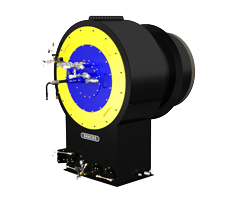

DDZG

Steam pressure atomizers

Capacity range

10 – 80 MW

Fuels

Light oil, heavy oil, gases (including special gases and process gases)

Applications

Water-tube boilers and thermal oil boilers with various geometries. Gas turbine flue gas burners in power plants, waste incineration plants

The main points

- Flexible burner concept

- Simultaneous combustion of multiple gases, also in combination with various liquid fuels

- Air preheating can be used up to 300°C

- Extremely low emissions

- Large control range

- Low operating cost thanks to high-efficiency combustion technology and low auxiliary power requirement

- Short planning phase thanks to modular design concepts

- Numerous pre-designed solutions as the basis for custom engineering

- In compliance with European Directives

One system for all applications in the high load range

The innovative DDZG steam pressure atomizer series sets new standards in terms of emissions, and is revolutionizing the steam pressure atomizer market and an innovative further development. The secret is simple: It is essentially not just a burner, but also a variable, modular building block system from which burners can be individually configured. That is what makes the DDZG highly flexible – while also delivering low NOx emissions that no competitor can match.

The components of the new system are based on SAACKE steam pressure atomizer technology proven thousands of times over. The range extends from inexpensive basic solutions to multi-fuel burners with several fuel lances for complex requirements, Ex-protection variants or air preheating up to 300°C.

As the core of process firing, the DDZG can burn even unconventional gases (e.g. with a high hydrogen content) safely and with low emissions. If required, it can burn different gases and liquids simultaneously with simultaneous firing, in a wide range of combinations. The SAACKE Engineering Team will find the optimum solution for your application too – just contact us to talk about it.

Despite this flexibility, the system's modularity ensures that the cost and labor commitment is kept highly competitive whatever the specific solution.

The new process concept keeps operating costs very low while at the same time delivering extremely low emissions. Low pressure losses minimize the power consumption of the fan.

The DDZG also sets new standards in terms of environmental protection, reliably conforming to very stringent limits. In typical applications, emission limit requirements between 50 and 80 mg NOx/m³ (at STP) for operation with natural gas and 100 to 150 mg NOx/m³ (at STP) for fuel oil have already been met. Under the right conditions even lower emissions can be achieved.

The high energy efficiency and low maintenance cost represent the results of decades of continuous development work.

With all its flexibility, the DDZG is uncompromising in just two attributes: high quality and extremely long service life.