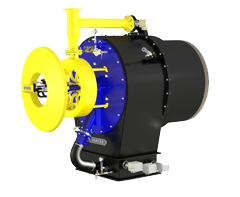

TF-DDZG

Capacity range

10 – 50 MW

Fuels

Heavy oil, natural gas, light oil as well as gaseous and liquid special fuels

Applications

Water-tube boilers, thermal oil boilers and process plants of varying geometry

The main points

- Exceptionally low emissions, especially for heavy oil unmatched at present

- Sturdy steam pressure atomizer technology

- Ideal for water-tube boilers, thermal oil boilers and process plants of varying geometry

- Air preheating can be used up to 300°C

- Large control range

- No additional flue gas recirculation system required

- Low operating cost thanks to high-efficiency combustion technology and low auxiliary power requirement

- In compliance with European Directives

Heavy oil emission values which set technical standards

When they were introduced, these burners of the TF-DDZG steam pressure atomizer series redefined the limit of what was feasible in terms of engineering, setting new technical standards for clean flue gas: Emission values are extremely low for every fuel, especially for heavy oil, reaching levels unmatched today.

The TF-DDZG is based essentially on proven SAACKE steam pressure atomizer technology. However, it has a specially adapted air flow with swirled, multiple-staged combustion air, which leads to considerable reduction in fuel NO, thereby drastically reducing emissions. The corresponding burner also allows for an especially short, stable flame, which can even be adapted to problematic furnaces. It is available as an oil burner, gas burner or dual fuel burner, thus ensuring especially flexible firing: the most economical fuel can be supplied depending on the market situation.

To counteract thermal NO effectively, an additional external flue gas recirculation channel system is typically installed, which involves a significant investment, takes up space and must be maintained. The TF-DDZG features recirculation of flue gas as an internal solution integrated into the burner concept: The special air flow draws back about 50% of the flue gas into the flame zone, thereby ensuring flawless burnout and especially low NOx values. All of this without any additional equipment overhead and with the same fan capacity.

Because it is designed as a duoblock burner (a burner with a separate fan), it can also be installed in virtually any mounting position, even in situations where space is problematic and in complex process firing systems. The sturdy design with long maintenance intervals – which make this an especially profitable investment – are what you naturally expect from SAACKE. Whatever the actual reason for the decision, choosing the TF is always a good decision. It ensures your plant will be able to continue to operate as emission requirements become even stricter.

With all its flexibility, the TF-DDZG is uncompromising in just two attributes: high quality and extremely long service life.